In the current day and age you will find that Fibre Reinforced Plastic (FRP) pultrusions are used in a wide scope of varied applications. This leads us to assess the various reasons as to why this is the case. Keeping that in mind, continue reading to discover what benefits pultrusion material has over additional types of materials.

There is only one place to begin and this is with the chemical and corrosive resistance that is associated with the materials produced via pultrusion machines. A lot of people and companies elect to utilise pultrusion materials for a fast scope of applications for the sheer fact that they are resistant to a lot of corrosive media. This includes everything from alkalis, to acids, to salts, over a varied and broad concentration and temperature range.

In addition to this, you should also consider the fact that these materials are strong yet lightweight at the same time. This is the perfect combination. Research shows that pultrusion materials have an approximate gravity of 1.8, which is two thirds of aluminium and one fourth of steel. When it comes to strength, pultrusion materials have a high flexural and tensile strength. There is literally no comparison when it comes to the likes of steel.

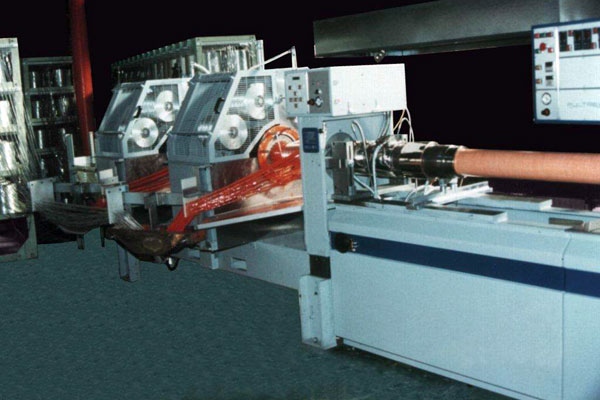

The strength factor is actually worth elaborating on, since it is one of the main advantages associated with this process. Caterpillar grippers or hydraulic grippers are used to pull downstream the many fibre bundles during the pultrusion process. This causes the fibre filaments to be in tension when curing in heated die. Fibres have higher strength values when in tension and this allows better compaction, because they are better aligned, meaning more fibres fit into a given volume. Because of this, all excess resin is squeezed out before it enters the die because fibre density is exceptionally high. This leads to an increase in weight, by roughly 70 per cent, and volume, be approximately 50 per cent, which is why FRP is so strong.

Pultrusion machines also provide a highly flexible product. One that can be created in various types, sizes and indeed colours. This is extremely beneficial, as it ensures you are guaranteed to have the exact product you require. You will not have to compromise.

Aside from the points that have already been mentioned, one of the key factors you need to consider is the fact that pultrusion machines represent real value for money. When it comes to the cost of pultrusion profiles, approximately 80 to 90 per cent is raw material costs. This is one of the chief reasons why pultrusion is one of the most widely used and fasted growing manufacturing processes. This is especially the case when you consider the fact that labour and machine costs are minimal.

All in all, hopefully you now have a better understanding regarding why pultrusion machines are so popular. It is not hard to see why this type of material is used for an extensive and varied scope of applications. The benefits are huge.